All activities developed by Newtesol are exhaustively monitored by the Quality Control Department.

The department carries out an IPP (Inspection Program Points) as a guide to develop and control the perfect task execution.

Newtesol develops these IPPs based on its customer technical specifications and complying with the codes and design rules of each part to be manufactured.

By applying these methods, total task traceability is achieved (materials used, tests completed, manufacture and inspection personnel qualification…). All these data are included in a final dossier that is handed to the customer.

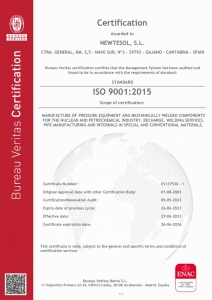

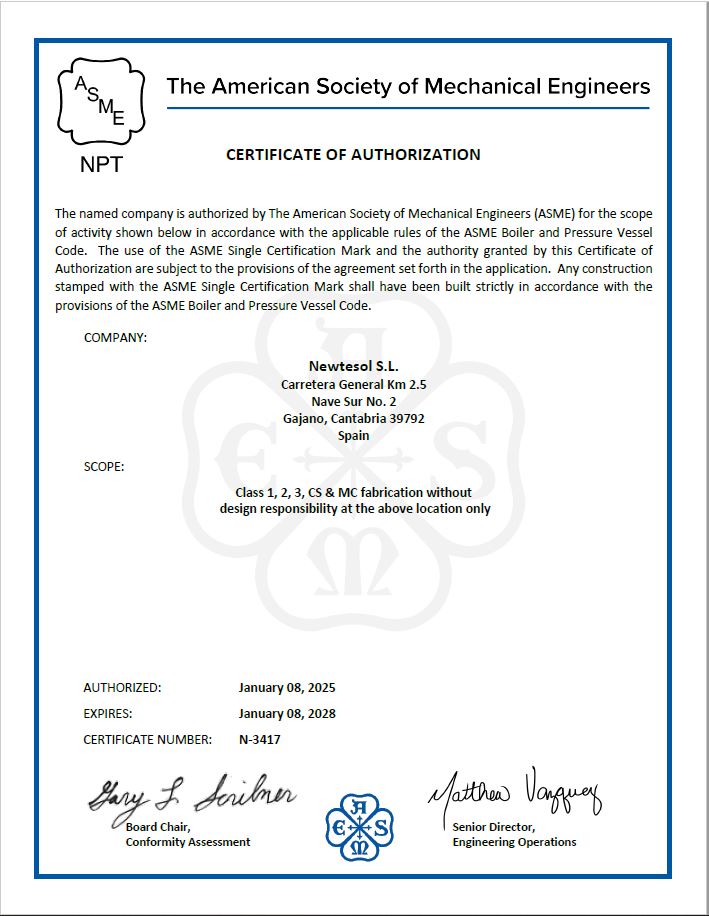

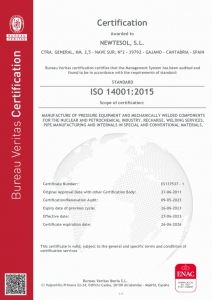

Newtesol counts with several quality certificates and stamps:

CERTIFICATES

- ISO 9001:2008

- DIN-EN 729-2 UNE EN-3834

- 10 CFR 50 App B By Safety Class 3 (SC)

- ASME III NCA-3800

ASME STAMPS

- U, ASME VIII Division 1

- U2, ASME VIII Division 2

- NPT, ASME III Division 1 (Nuclear)

At the non-destructive department essays are made following our customers´ specifications or the corresponding code.

Newtesol counts with qualified equipment and personnel to do the following essays:

- Penetrating liquids

- Utrasonics

- Magnetic particles

- PMI (Possitive Material Identification)

- Radiographic exams

- Hardness exams

- Hidraulic test

- Ferrita control

- Ferricyanide essay